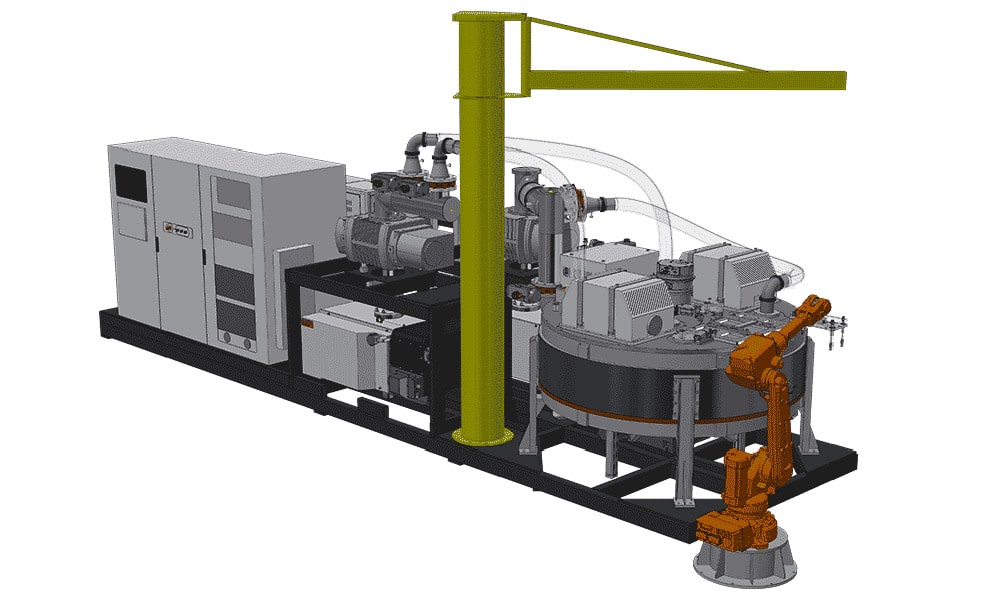

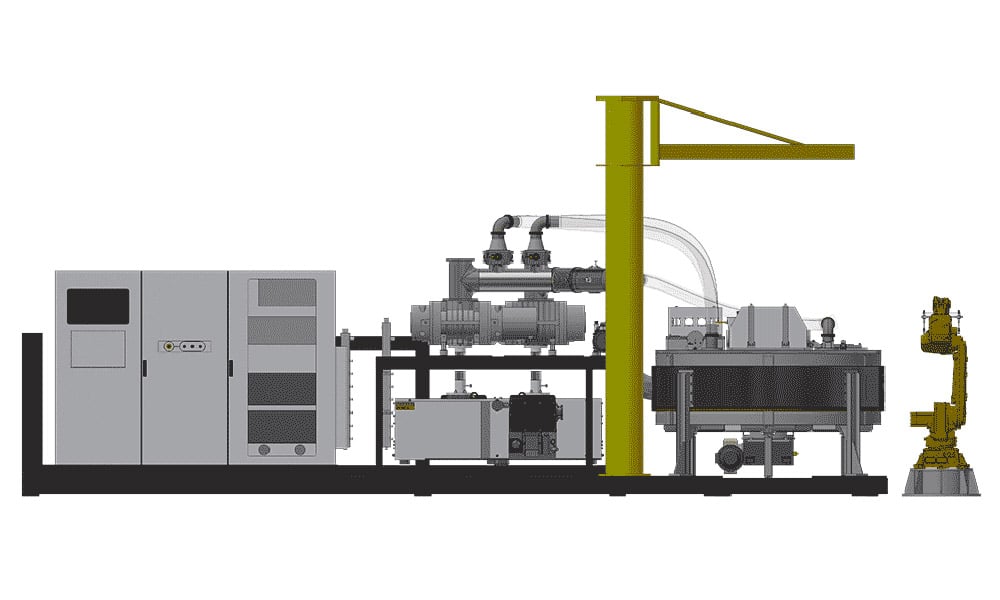

Twist-Met automated system

Twist-Met represents the next generation of low-cost automated sputtering equipment, suitable for the decoration sector. It runs in fully automatic mode with a 40-second cycle time.

Despite being a highly productive industrial sputtering machine, one of its main advantages is the ability to maximize space thanks to its overall compact design.

Other advantages offered by Twist-met:

Eliminates/reduces labour costs

Eliminates piece-holder tools and related maintenance, cleaning and storage costs

Reduces the production of scrap pieces while improving quality

Constant profitability over a 24-hour period

Just like other solutions designed, developed and installed by Arzuffi, Twist-Met finds application across a wide range of industries, e.g. automotive, cosmetics, technology, high fashion and many others.

We are at your complete disposal for the supply of a high-tech high-vacuum metallization system. Do not hesitate to contact us for further details or to request a personalized quote.

We deliver our products and services throughout Italy and all over the world.

TWIST-MET V1

Useful coating area: 530 x 330 x 225 mm

Number of trays: 1

Chamber size: 690x450x310 mm

Coating process: CHAMBER 1 loading/unloading – CHAMBER 2 ionic discharge – CHAMBER 3 Sputtering – CHAMBER 4 PECVD

Coating technology: medium frequency

Cycle time: 40 seconds

Characteristics: space optimization thanks to its compact design

TWIST-MET V3

Useful coating area: 530 x 760 x 270 mm

Number of trays: 1

Chamber size: 640x880x350 mm

Coating process: CHAMBER 1 loading/unloading – CHAMBER 2 ionic discharge – CHAMBER 3 Sputtering – CHAMBER 4 PECVD

Coating technology: medium frequency

Cycle time: 40 seconds

Characteristics: space optimization thanks to its compact design