High vacuum coating machinery

With a well-established global presence, Arzuffi designs, manufactures and supplies thin film deposition systems across the globe. Our equipment has been operating in a variety of sectors such as automotive, lighting, cosmetics and pharmaceutical packaging, household appliances, glassware and spirits and many others. A true hallmark of high performance, excellent quality of coating and reliability.

Our machines employ some of the most advanced technologies. They coat almost any material such as metal, ceramic, glass, and polymers such as ABS, PP, PE, PET, and PC and can also cover complex 3D geometries.

The deposition of the metal is performed by different techniques:

- Sputtering: thin layers of material are deposited on a surface using accelerated ions or atoms from a solid target.

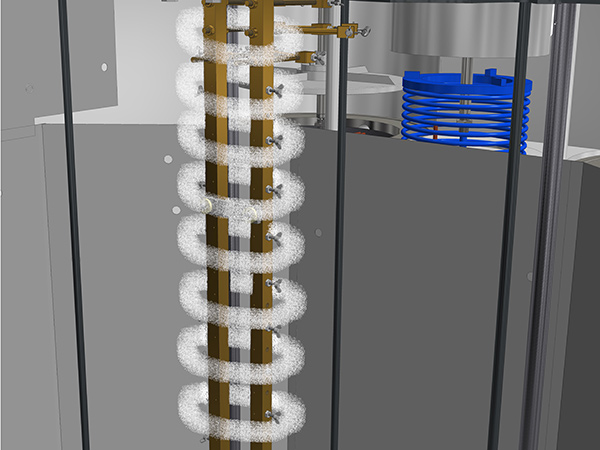

- Thermal evaporation: a high-intensity current sublimates the material to be deposited.

- Combined technology: sputtering and thermal evaporation come into action within the same chamber.

- PECVD plasma: a plasma is used to generate thin films from gaseous precursors, creating advanced coatings with specific properties.

Sputtering

Our systems can feature the installation of one or more magnetron cathodes. The sputtering process uses a magnetic field to improve the efficiency of target erosion, whether metal or alloy, by generating thin coatings on substrates through ion acceleration.

Combined technology

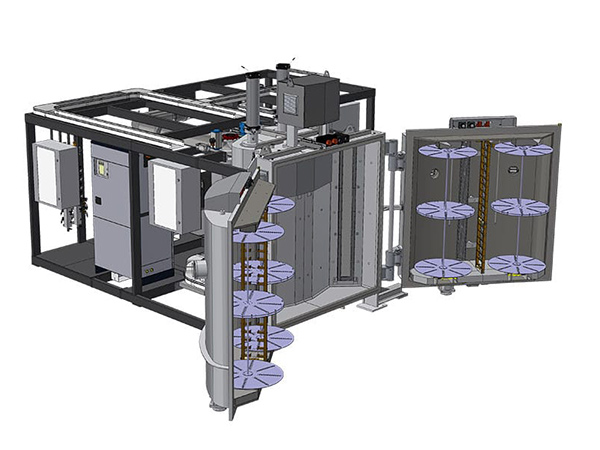

In order to provide more flexibility in process set-up and expand the available options of materials that can be deposited, Arzuffi offers the possibility of combining magnetron sputtering and thermal evaporation technology in the same system.

Thermal evaporation

Since its founding, Arzuffi has gained a global reputation for its expertise in the construction of thermal evaporation metallizing equipment. This technique makes use of a high intensity current to sublimate the material (usually aluminum) that will be deposited on a surface. Due to the high vacuum pressure, the particles can quickly reach the substrate even at substantial distances. We offer a variety of product lines, including AM/KW, Speed-Met, Hor-Met, with different available configurations.

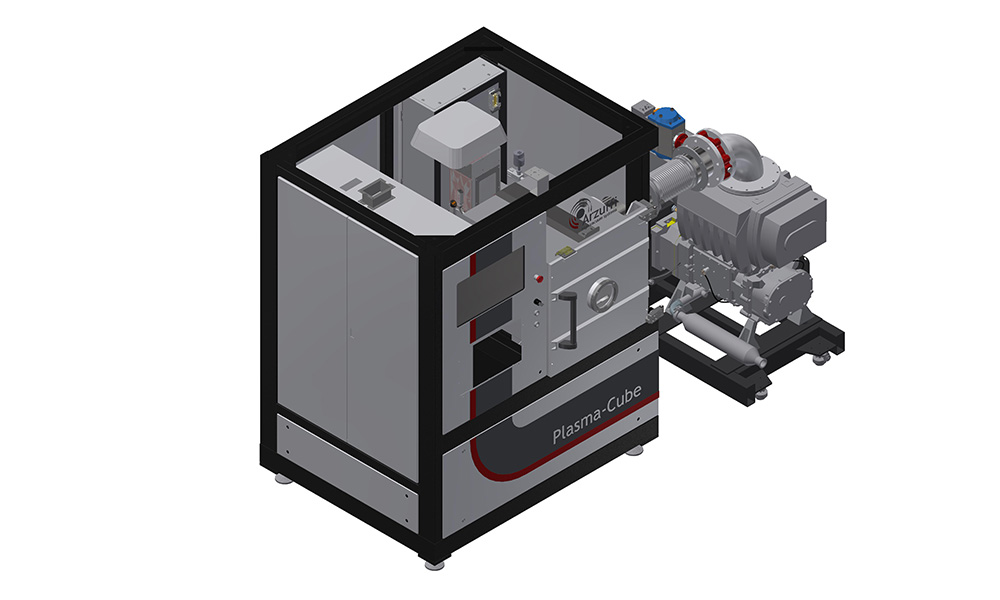

Plasma PECVD

Offering a diverse range of applications, such as deep cleaning, degreasing, activation, and surface pre-treatment, Arzuffi’s PECVD systems aim to set a standard of excellence in the surface treatment industry.

Compact and customized solutions

Starting from the order placement to the design phase, delivery and on-site assembly, the sole focus of our company is to supply our clients with state-of-the-art, innovative technologies in a compact and solid layout.

The excellent expertise of our team translates into the construction of custom-made systems, conceived to guarantee ease of use during maintenance and to optimize production efficiency.

We are readily available to offer consulting and personalized assistance for every client. Our presence extends beyond Italian borders, as we serve clients worldwide.