High-vacuum metallization processes

Arzuffi designs and manufactures customizable PVD machinery with an aim to satisfying any type of customer demand. Our research and development team works side by side with our specialized technicians and process engineers to find cutting-edge solutions and achieve excellent quality.

Based on the technologies employed, Arzuffi metallization systems fall under 4 main categories:

Thermal evaporation

Sputtering/reactive sputtering

Combined thermal evaporation and sputtering technology

Plasma

These categories are broken down according to each basic machine process, namely: sputtering/reactive sputtering, thermal evaporation, anti-scratch technology, cathodic arc deposition and hydrophilic/hydrophobic treatment.

Contact us to request more information on the supply of our high-vacuum metallization processes and systems. We install our systems in Italy and all over the world.

Reactive sputtering

Reactive sputtering is used for depositing coloured coatings on substrate surfaces. It involves injecting additional gases (typically argon) to the standard sputtering process to obtain a set of coloured thin films ranging from gold to red and blue. Black chrome and gold rose are just some of Arzuffi’s most sought-after colour effects.

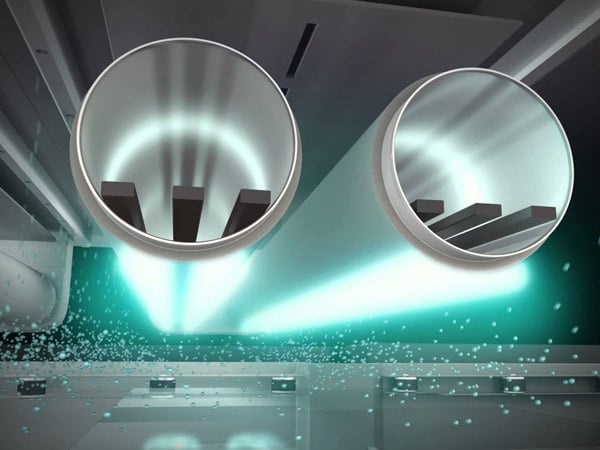

Sputtering

Sputtering (cathodic pulverization), a type of physical vapour deposition technique used for creating thin films, is based on gas ion bombardment of a target material. Unlike other vapour deposition techniques, the thickness of the deposited material can be controlled with precision so as to obtain fully metalized or semi-transparent surfaces.

Thermal evaporation

Through thermal evaporation, the target material is heated by Joule effect, which involves the transformation of electricity into thermal energy or other sources. Tungsten filaments are heated inside a chamber causing the source material to evaporate and condensate on the substrate surface. High-vacuum allows obtaining optimal adhesion in a relatively short time.

Anti-scratch

This treatment provides surfaces with particular abrasion resistant properties, and is obtained through an exclusive process developed by Arzuffi, known as AHC (Arzuffi Hard Coating). The technique involves changing the surface tension of the substrate to increase hardness, thus reducing the production of scrap pieces resulting from improper handling.

Cathodic arc deposition

Cathodic arc deposition is a physical vapour deposition technique in which an electric arc is generated on the surface of the metal to be deposited. The arc melts the coating material by means of a high-energy electric discharge that is forced to travel through the metal target located inside a vacuum chamber until all fragments evaporate.

Hydrophobic / Hydrophilic

Hydrophobic coating is used to make a surface completely water – repellent. The water that comes into contact with the prepared product does not turn liquid but is deposited in the form of spheres.

Hydrophilic coatings increase the wettability of treated surfaces. Water exploits the various atomic bonds that form on the surface, producing thin films instead of liquid droplets. The coating’s hydrophilic property causes water films to evaporate faster than liquid droplets, resulting in lower energy due to shorter drying times.