The glass bottles decoration industry is going to see a burst of innovation with the development of Arzuffi’s Line-Met G. This revolutionary equipment is designed to help companies produce and decorate glass bottles faster and more efficiently. This equipment boasts a cycle time of only 60 seconds and an unprecedented level of productivity and quality coating. With rejected pieces equal to zero, the Line-Met G is the ideal solution for those seeking maximum output and superior results.

The Line-Met G has been designed to work with a variety of glass bottles, such as those for cosmetics (perfumes and diffusers) and alcohol (spirits and beverages) industries. The Line-Met G can coat bottles with a maximum diameter of 315 mm and a maximum height of 400 mm, so even large bottles can be processed with ease. Line-Met G can be customized to fit a variety of layouts and combinations of trays. As an example, one possible configuration of Line-Met G can coat from 5 to 30 bottles per minute depending on the diameter which can be up to 315 mm.

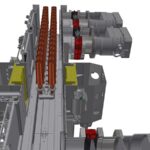

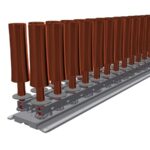

The equipment consists of three chambers: loading and plasma etching, dynamic sputtering deposition, and unloading. Line-Met G is able to guarantee a uniform deposition thanks to the innovative dynamic sputtering system designed by Arzuffi technical engineers which enables to obtain an high plasma density.

With its unmatched cycle time, superior coating quality and nearly zero reject pieces, the Line-Met G is a revolutionary industry-leading equipment. Arzuffi is proud to offer this equipment to companies in the glass bottle decoration industry who are seeking maximum efficiency, superior quality results, high-end technology, and of course very high productivity.