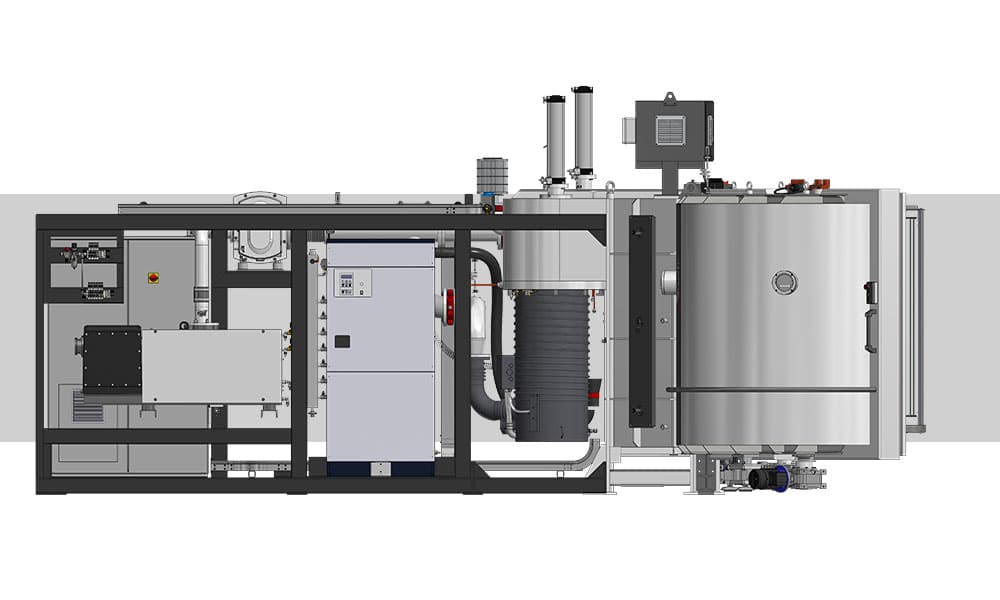

Combined-technology coating system

Two technologies integrated into a single system? Believe it or not, this is possible thanks to Combi-Met, our combined high-vacuum coating solution where both sputtering and thermal evaporation processes occur in the same chamber.

This line comes in 4 different configurations, each one differing from one another in terms of chamber size, loading modes and work cycle times: for example, Big Chamber and Orizontal take between 6 and 20 minutes, while Single Planet and Double Planet take between 4 and 9 minutes.

The system also employs different coating processes, such as: ionic discharge, PECVD base coat /top coat (HMDSO), thermal evaporation, sputtering / reactive sputtering, AHC (Arzuffi hard coat) and SiO2

The advantages offered by the Combi-Met line include flexibility in switching from one coating technology to another in a few seconds, not to mention multiple coating phases that can be performed in a single cycle (multilayer coating).

If you are looking for a fully customized combined-technology system for high-vacuum chrome-plating of materials, do not wait any longer. Contact us now! We deliver our products and services throughout Italy and all over the world.

Batch Manual Solution

Combi-Met

Available in 4 configurations, the Combi-Met line includes high-vacuum coating machines that use both sputtering and thermal evaporation technologies. Ideal for treating objects of different sizes and shapes, this system fits perfectly into any type of industrial line production process.