Combi-Met: Two technologies in a single solution

Sputtering, plasma treatment and thermal evaporation are the main technologies employed by our high-vacuum metallization systems.

Depending on the customer’s needs and production purposes, the Arzuffi team designs, develops and installs fully fitted machines such as Combi-Met, an extremely sophisticated solution that combines sputtering and thermal evaporation.

Combi-Met, in all its possible configurations, is extremely flexible and as such is able to switch from one deposition technology to another in just a few seconds, obtaining multi-layer coatings

If you are looking for a metallization system that goes beyond conventional chrome-plating processes, contact us to request information on our high-vacuum machinery.

We export our experience and know-how all around the world.

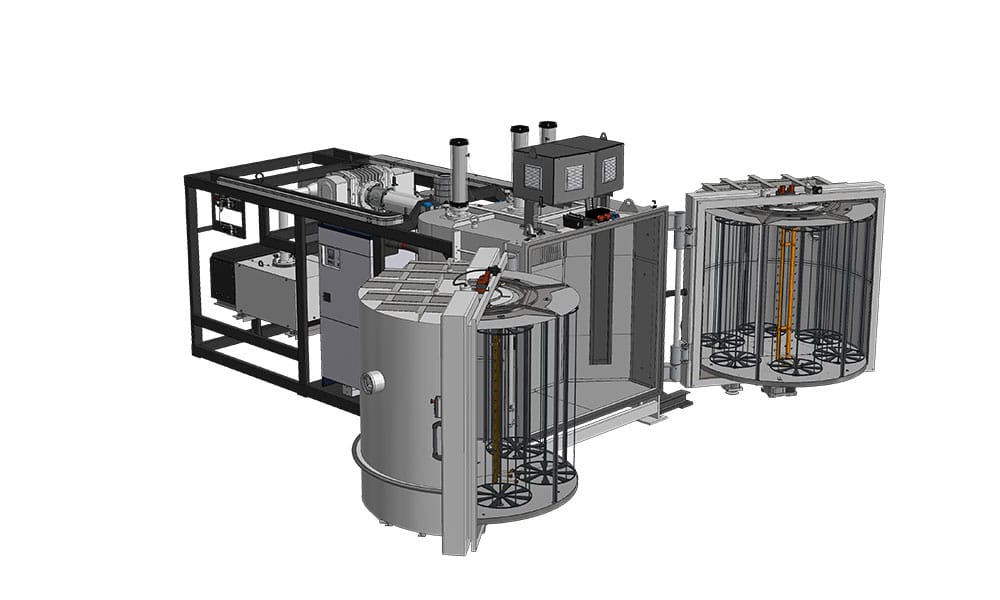

COMBI-MET BIG CHAMBER

Chamber diameter: 1900 mm

Chamber height: 1800 mm

Number of fixtures: 6-7-8-10-12

Fixture diameters: 560-540-490-440-360 mm

Useful coating height: 1500 mm

Cycle time: 7-20 minutes

Characteristics: Suitable for a wide variety of substrates with different shapes

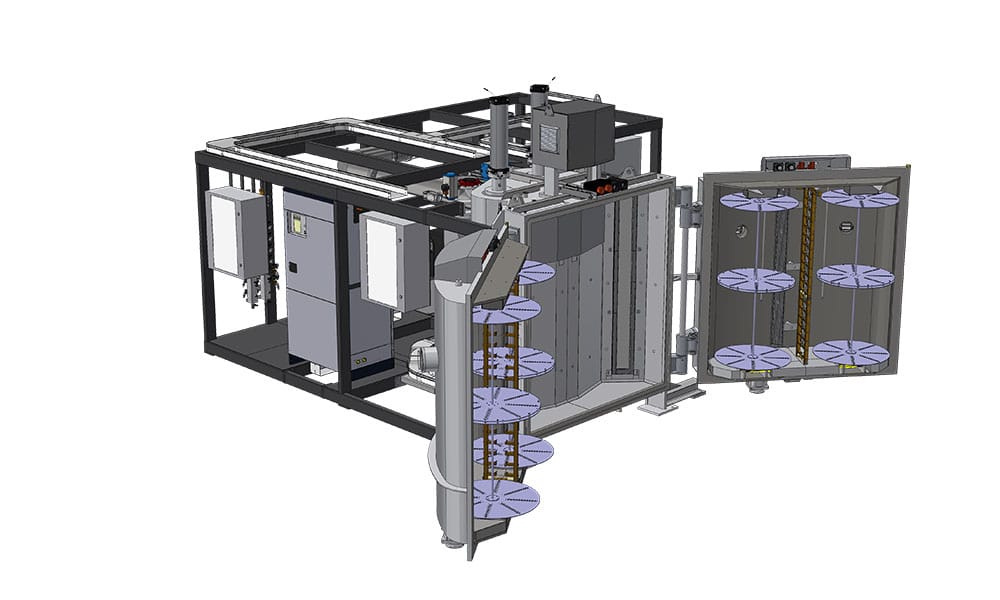

COMBI-MET SINGLE PLANET

Chamber diameter: 1100 mm

Chamber height: 1800 mm

Number of fixtures: 1

Fixture size: 960 mm

Useful coating height: 1600 mm

Cycle time: 4-9 minutes

Characteristics: Suitable for line production

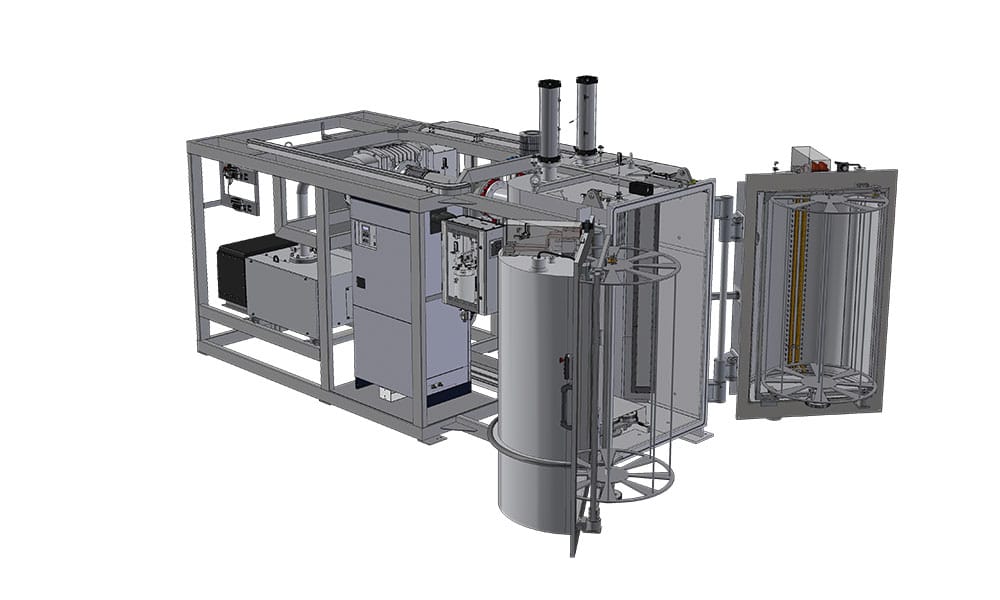

COMBI-MET DOUBLE PLANET

Chamber size (L x W x H): 1800 x 900 x 1800 mm

Number of fixtures: 2

Fixtures size: 560 mm or 710 mm

Useful coating height: 1500 mm

Cycle time: 4-9 minutes

Characteristics: Suitable for line production

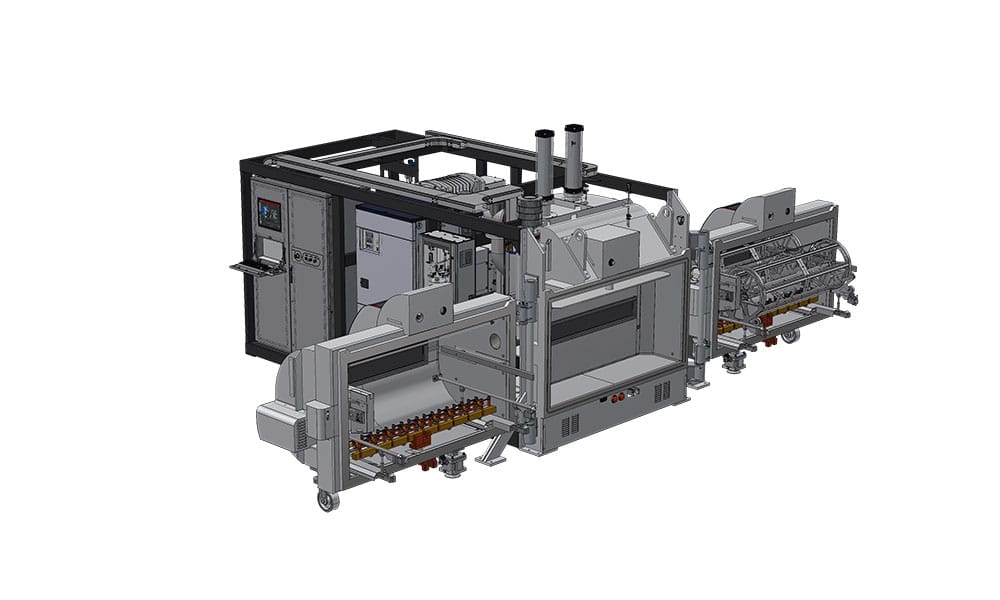

COMBI-MET HORIZONTAL

Chamber size (L x W x H): 1900 x 1000 x 1300 mm

Number of fixtures: 2

Fixtures size: 560 mm

Useful coating height: 1500 mm or 2400 mm

Cycle time: 6-10 minutes

Characteristics: Suitable for a wide range of small pieces or a single large piece