- Test-Met EV (thermal evaporation technology)

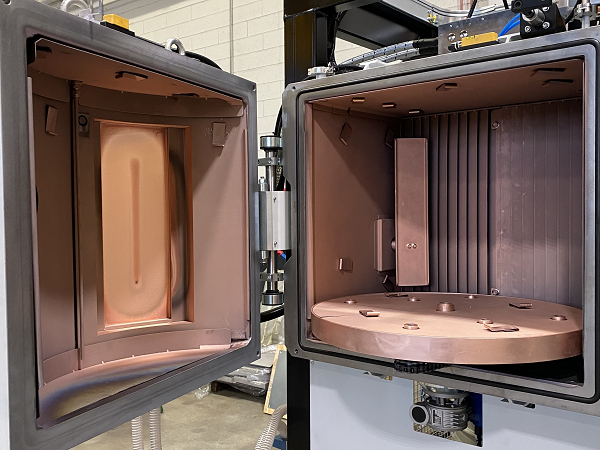

- Test-Met SP (sputtering technology)

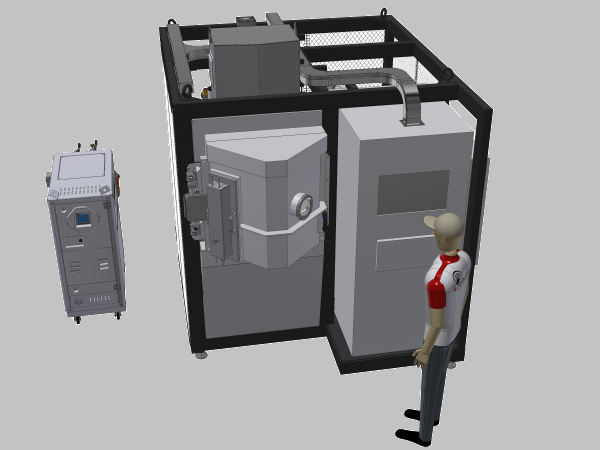

During the first months of 2024, the Arzuffi technical team designed and projected new versions of Test-Met, which will be manufactured and turned on in the coming months at Arzuffi’s production area. Specifically, these are systems designed to metallize small production batches, taking up the technical solutions to hold the substrates which are typical of standard systems (e.g.: use of bars for plastic cosmetic packaging; planetary with rotation for glass bottles and flasks), but realised in a mini version. Below are some productivity examples:

- caps ⌀ 30mm ⭢ 8 caps x bar; 30 bars x satellite; 240 caps x cycle

- bottles ⌀ 120mm h 300mm(max) ⭢ 12 bottles x cycle

- bottles ⌀ 250 mm h 300 mm(max) ⭢ 4 bottles x cycle

Several configurations are available: magnetron sputtering technology, thermal evaporation or a combination of both, depending on customer requirements. Test-Met is equipped with the Arzuffi standard components, synonymous with quality and reliability, but feature a small-sized chamber (useful area diam. 650 mm x height 480 mm), which can be customised on request. The low investment price, the compactness and usability of the system, and the low energy consumption make Test-Met an interesting equipment for various sectors and applications.