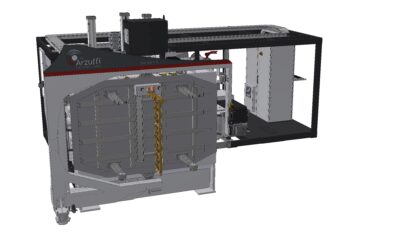

Speed-Met II Double Face: revolutionizing cosmetic packaging metallization

In the world of cosmetic packaging metallization, efficiency and innovation are key elements. We are happy to present Speed-Met II Double Face, an advanced solution that leverages a well-established technology for Arzuffi. It is designed to optimize continuous...

Forvia Hella chooses Arzuffi

We are proud to announce that the FORVIA HELLA Group has chosen Arzuffi PVD for the development of its fully automated PVD line in Mexico: a state-of-the-art plant for the metallization and protective coating of automotive components. A significant milestone that...

Paris Packaging Week – January 28 & 29, 2025

We are happy to participate at the Packaging Week Paris. Join us on January 28 and 29, 2025 for this important event dedicated to those who work in the world of packaging! +14,000 attendees; +2,900 brands and agencies; +750 suppliers; +160 expert speakers.

Surface treatment: Vacuum Italia and the partnership with Arzuffi

In the surface treatment field, Vacuum Italia stands out for innovation, precision and reliability. Today we want to celebrate their history, the values that guide them and their growth, made possible also by the collaboration with Arzuffi, a partnership we are...

P&E Coating Days – October 23rd & 24th

We are thrilled to be among the sponsor companies of the P&E Coating Days, an unmissable event for all professionals in the paint and surface coatings sector. On October 23rd and 24th you can find us in Milan, at the Leonardo da Vinci Museum of Science and...

Cryogenic vacuum systems

Cryogenic systems are key to improving vacuum deposition by reducing moisture contamination and optimizing vacuum chamber performance. Goal of vacuum systems The purpose of a vacuum is to reduce the density of free gas molecules in a chamber, thereby reducing the...

AHC, Arzuffi Hard Coating process

We are kicking off a new informative section of the blog: Arzuffi loves Innovations. All the technologies, processes and technological innovations developed over more than 35 years by the Arzuffi company explained in a simple and easy way. Let’s start with the AHC!...

Arzuffi Open Factory

We are thrilled to announce a special event which will take place at Arzuffi facility from June 10th June 16th 2024: Arzuffi Open Factory One full week dedicate to our Customers and potential Customers. We give the possibility to test our Fast-Met sputtering system...

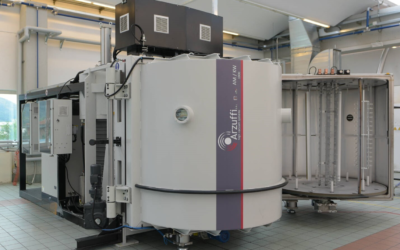

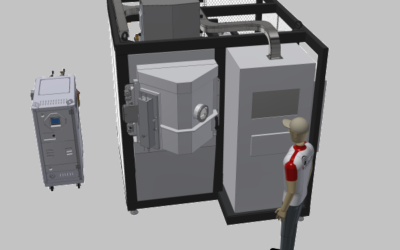

Test-Met: new versions release

In 2023, Arzuffi launched a new series of equipment called Test-Met: compact vacuum coating systems with small to medium-sized chambers and low energy consumption to meet new market demands. In fact, a new request is emerging for systems easy to use, with a compact...

Arzuffi and P&P Group combine to create Europe’s leading PVD surface treatment group

Official statement - Dec. 15, 2023 Arzuffi and the P&P Group, consisting of Protec Surface Technologies and Protim, have decided to join forces, creating a new giant in the vacuum coating industry. The union of these three leading players, each with unique skills...

Customer spotlight: 10 questions with ZKW Group

Bright Minds, Bright Lights: this is the motto of ZKW Group, a company specialized in the production of innovative premium lighting systems and electronics for international automotive manufacturers with a total of twelve locations worldwide. The portfolio includes...

Customer spotlight: 10 questions with HELLA

In this new episode we are thrilled and honored to introduce one of our most esteemed customer and globally renowned automotive supplier: HELLA. HELLA is a leading German automotive technology company known for its innovative solutions in the fields of Lighting,...

Customer spotlight: 10 questions with ELVEZ

Welcome to this exclusive interview with Dr. Žiga Gosar, director of the research, development and technology department at ELVEZ. ELVEZ is a family-owned company specialized in manufacturing and providing clients worldwide with plastic injection components,...

Customer spotlight: 10 questions with Hrastnik1860

Welcome to this exclusive interview with Mr. Kristjan Šiftar, Head of Decoration at Hrastnik1860. Hrastnik1860 is a renowned company known for its rich heritage and excellence in the development and production of premium glass packaging in the segment of spirits and...

Customer spotlight: 10 questions with …

Introducing "Customer Spotlight: 10 Questions with …" - a captivating blog series that delves into the experiences, insights, and success stories of our esteemed customers. In this engaging interview-style format, we sit down with a diverse range of individuals and...

Thermal Evaporation vs Magnetron Sputtering: A comparison

Two popular and essential methods widely employed in the creation of thin film coatings for decorative applications are thermal evaporation and magnetron sputtering. Both technologies offer unique advantages and cater to different applications in the industries. So,...

Vacuum metallization of Cosmetic packaging

Mascara tubes, lipstick, caps, closures, perfumes, jars, bottles: when it comes to cosmetic packaging, the metallization is a powerful and convenient technique. It greatly enhances the aesthetics of the product and makes a lasting impression on customers, adding a...

ADP, Advanced Deposition Process by Arzuffi

What is ADP? ADP, acronym for Advanced Deposition Process, is the innovative process developed by Arzuffi company that improves the evaporation phase, triggering a plasma process in the high vacuum phase. How does ADP work? During standard evaporation processes, the...

Revolutionizing surface performance with Arzuffi’s cutting-edge PECVD equipment

The world of surface treatments is witnessing a paradigm shift with the new Plasma Enhanced Chemical Vapor Deposition (PECVD) equipment developed by Arzuffi called Plasma-Cube. This breakthrough technology comes at a time when companies across various industries are...

The demand of metallized components in the automotive industry

In the past decade the automotive lighting industry has gone through a dramatic shift. Gone are the days of big shining headlights and simple aluminum metallization on injection molded plastic. In fact, in the past, aluminum metallization was used extensively in...

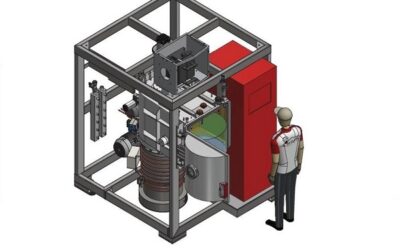

Test-Met: plug&play vacuum systems

Arzuffi has developed a series of high vacuum systems known as Test-Met, which has a broad area of application: sampling and color matching, mold testing, process research and laboratory tests. The market is demanding a flexible, affordable and compact equipment, easy...

LINE-MET G: glass bottles coating without limit of dimension

The glass bottles decoration industry is going to see a burst of innovation with the development of Arzuffi's Line-Met G. This revolutionary equipment is designed to help companies produce and decorate glass bottles faster and more efficiently. This equipment boasts a...