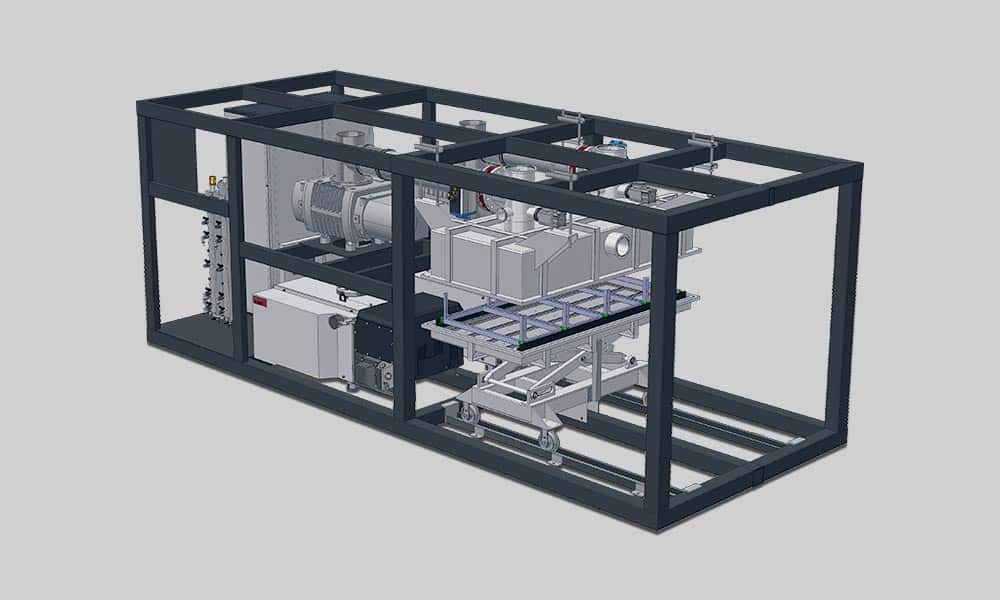

Plasma-Met: plasma surface treatment machine

Plasma–Met, specifically designed for plasma surface treatments, has the ability to change the surface tension of the substrate, thus ensuring excellent adhesion of the deposited layers.

Plasma-Met employs the following coating processes: Ionic discharge, PECVD (HMDSO) base coat and top coat – AHC (Arzuffi hard coat) – SiO2

The underlying potential of plasma technology is its ability to retain the treated product’s original physical features despite being completely transformed by the chemical surface treatment. This allows preparing the product for subsequent processes, such as painting or decoration.

Rely on us for the supply of a customized high-vacuum machine fitted with a plasma deposition chamber. We design, manufacture and install our machines for customers in Italy and around the world.

PLASMA-MET

Chamber size (L x W x H): 1700 x 6000 x 400 mm

Number of trays: 2 or 4

Tray sizes: 820 x 450 x 290 mm each

Layout (L x W x H): 5600 x 2200 x 2200 mm

Cycle time: 60 seconds